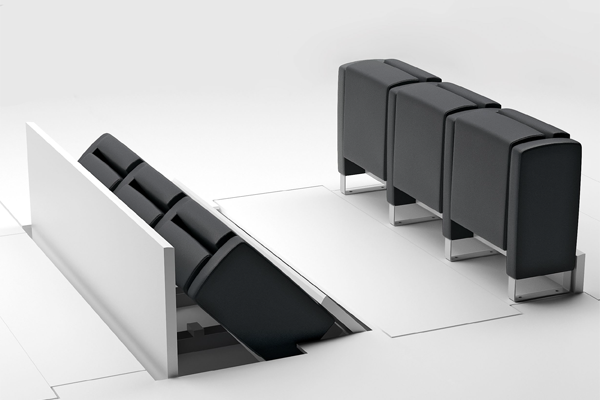

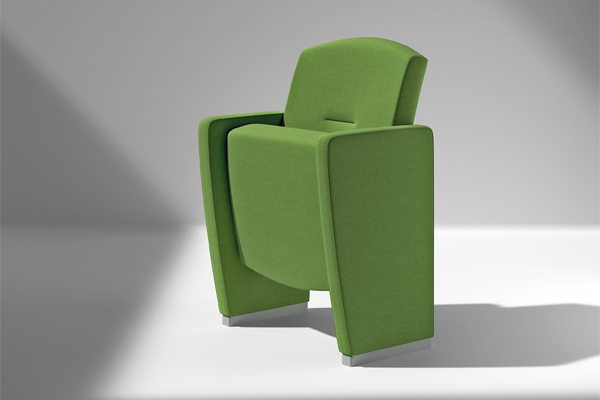

Cassiano

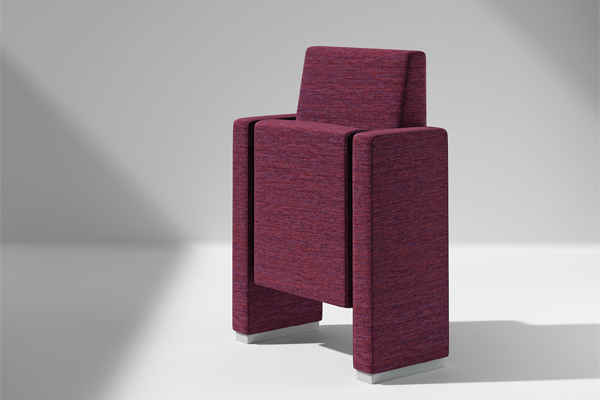

Cassiano is a compact, streamlined armchair mounted on a central base. Its individual floor-mounting system and integrated armrests make it ideal for installation in tight curves.The foldable version is specifically engineered for use with mobile tribune technology.